Unlocking Efficiency with Multi-Spindle Coil Winding Machines #

Multi-spindle coil winding machines are engineered to streamline the production of electric coils, offering significant improvements in efficiency, accuracy, and versatility. This guide provides an in-depth look at the advantages, applications, and available models of these machines, as well as answers to common questions about their operation and industry relevance.

Advantages of Multi-Spindle Automatic Coil Winding Machines #

-

Simultaneous Winding Operations

Multi-spindle machines enable multiple winding tasks to be performed at once, dramatically reducing production time and boosting throughput—an essential benefit for mass production environments. -

Precision and Consistency

These machines deliver superior accuracy, ensuring each coil meets strict specifications and standards, which minimizes the risk of defects and enhances product reliability. -

Versatile Functionality

Designed to accommodate a wide range of coil winding needs, these machines are suitable for transformers, electric motors, inductors, relays, and more. -

User-Friendly Operation

With a straightforward design, operators can quickly learn to use the equipment, reducing training time and associated costs. -

Advanced Automation

Features such as automatic coil changing, parameter adjustment, and fault detection reduce the need for constant supervision, lowering labor costs and supporting unmanned production lines. -

Customizable Solutions

Machines and turnkey solutions can be tailored to specific customer requirements, supporting the integration into fully automated factory environments.

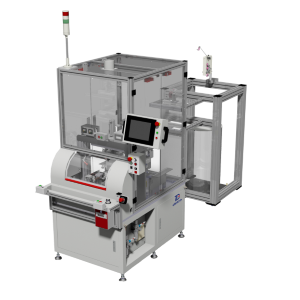

Product Range: Multi-Spindle Coil Winding Machines #

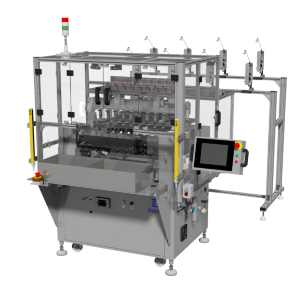

Automatic 8 Spindles Coil Winding Machine

Automatic 8 Spindles Coil Winding Machine

Automatic 8 Spindles Bobbin Coil Winding Machine

Automatic 8 Spindles Bobbin Coil Winding Machine

Automatic 8 Spindles Horn Coil Winding Machine

Automatic 8 Spindles Horn Coil Winding Machine

Automatic 8 Spindles Transformer Coil Winding Machine

Automatic 8 Spindles Transformer Coil Winding Machine

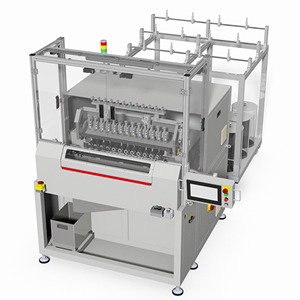

Automatic 12 Spindles Coil Winding Machine

Automatic 12 Spindles Coil Winding Machine

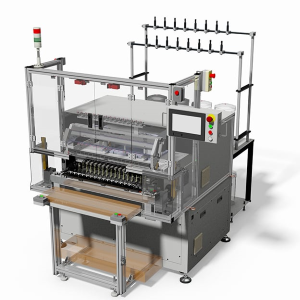

Automatic 16 Spindles Coil Winding Machine

Automatic 16 Spindles Coil Winding Machine

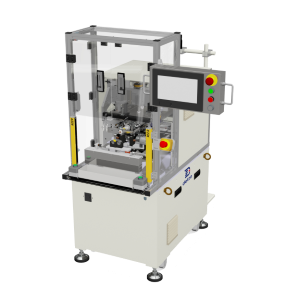

Automatic 4 Spindles Coil Winding Machine

Automatic 4 Spindles Coil Winding Machine

Automatic 6 Spindles Coil Winding Machine

Automatic 6 Spindles Coil Winding Machine

Automatic Single Spindle Coil Winding Machine

Automatic Single Spindle Coil Winding Machine

Automatic Single Spindle Vertical Coil Winding Machine

Automatic Single Spindle Vertical Coil Winding Machine

Automatic 4 Spindles Coil Winding Machine

Automatic 4 Spindles Coil Winding Machine

Benchtop Single Spindle CNC Coil Winding Machine

Benchtop Single Spindle CNC Coil Winding Machine

Benchtop 2 Spindles CNC Coil Winding Machine

Benchtop 2 Spindles CNC Coil Winding Machine

Benchtop 4 Spindles CNC Coil Winding Machine

Benchtop 4 Spindles CNC Coil Winding Machine

Benchtop Single Spindle CNC Air-Coil Winding Machine

Benchtop Single Spindle CNC Air-Coil Winding Machine

Automatic 8 Spindles Air-Coil Winding Machine

Automatic 8 Spindles Air-Coil Winding Machine

Frequently Asked Questions #

What is an Automatic Winding Machine? #

Automatic winding machines use automation to wind electric coils into various electronic components, motor parts, and related products, following the required shape, number of layers, and sizes.

How Does an Automatic Wire Winder Machine Work? #

The process begins with positioning the electric coil. The operator inputs design specifications—such as the number of winding layers, diameter, direction, and coil count—into the control system. The machine then executes rotation, vertical, and transverse movements to complete the winding. Upon completion, the machine performs coil finishing to ensure integrity and usability.

What is the Purpose of Automatic Coil Winding Machines? #

These machines are primarily used to manufacture electric coils, which consist of a core and one or more enameled copper wires wound in a spiral. When current passes through the coil, it generates a magnetic field, and vice versa. Electric coils are fundamental components in electronic, electrical, and communication devices.

What are the Applications of Automatic Winding Machines? #

- Inductor: Used in sensors (temperature, pressure, light) to convert physical changes into electrical signals.

- Transformer: Regulates voltage for effective power transmission and distribution.

- Electric Motor: Produces rotational motion via a rotating magnetic field.

- Communication Equipment: Utilized in antennas and radios for electromagnetic signal processing.

- Electronic Circuits: Essential in filters, oscillators, and amplifiers to modify signal characteristics.

Which Industries Use Automatic Electric Coil Winding Machines? #

- Electronic Product Manufacturing: For winding inductors, transformers, and other components.

- Motor Manufacturing: For winding motor coils, enhancing efficiency and performance.

- Energy Industry: For generator coils and solar panel manufacturing.

- Transportation: For engines, transmissions, and other vehicle components.

- Wind Energy: For wind turbine coils, ensuring efficient operation.

How Much Does an Automatic Winding Machine Cost? #

Pricing depends on specifications such as spindle count, pitch range, winding width, turn resolution, spindle speed, torque, wire diameter, power supply, dimensions, and weight. For a detailed quotation, customers are encouraged to share their specific winding requirements.

What Types of Automatic Winding Machines are Available? #

The product lineup includes multi-spindle coil winding machines, inductor winding machines, air-coil winding machines, flat-wire winding machines, and motor stator winding machines.

Related Categories #

- Multi-Spindle Coil Winding Machine

- Customized Turnkey Solutions

- Soldering Machine

- Motor Stator Winding Machine

- Air-Coil Winding Machine

- Pin Insertion Machine

- Taping Machine

- Inductor Winding Machine

- Customised Assembly Machine

- Flat-Wire Winding Machine