Elevating Coil Manufacturing with DETZO Inductor Winding Machines #

DETZO stands at the forefront of inductor winding technology, offering a suite of machines engineered to streamline production, enhance reliability, and meet the evolving needs of modern manufacturing.

Why Choose DETZO Inductor Winding Machines? #

DETZO’s inductor winding machines are recognized for their:

- User-Friendly Design: Intuitive interfaces and advanced technology simplify operation and setup.

- Versatility & Precision: Flexible functionality ensures high accuracy for a wide range of winding requirements.

- Automation: Automatic feeding and operational features minimize manual intervention, reducing downtime and increasing productivity.

- Wide Applications: Suitable for diverse use cases, from electronics to automotive, telecommunications, and renewable energy sectors.

Whether optimizing an existing process or scaling up production, DETZO’s solutions are designed to deliver consistent performance and reliability.

Application Versatility #

DETZO inductor coil winding machines are adaptable to multiple industries, including:

- Electronics manufacturing

- Automotive components

- Telecommunications

- Renewable energy

Their ability to produce high-quality coils ensures compliance with the stringent standards of contemporary manufacturing. For those seeking a holistic approach, DETZO also provides one-stop winding solutions tailored to specific production needs.

Featured Inductor Winding Machines #

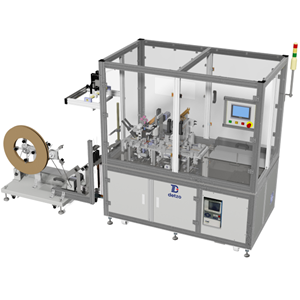

Automatic Bifilar-Type Multilayer Inductor Winding Machine

Automatic Bifilar-Type Multilayer Inductor Winding Machine

Automatic 10 Spindles Inductor Winding & Soldering Machine

Automatic 10 Spindles Inductor Winding & Soldering Machine

Automatic Inductor Soldering Machine

Automatic Inductor Soldering Machine

Automatic Inductor Coreless Winding Machine

Automatic Inductor Coreless Winding Machine

Automatic 2 Spindles Inductor Winding Machine

Automatic 2 Spindles Inductor Winding Machine

Automatic Inductor Cover Assembly Machine

Automatic Inductor Cover Assembly Machine

Automatic Alpha Coil Winding Machine

Automatic Alpha Coil Winding Machine

Automatic Flat-Wire Inductor Winding Machine

Automatic Flat-Wire Inductor Winding Machine

Automatic Core Gluing Machine

Automatic Core Gluing Machine

Automatic 8 Spindles Air-Coil Winding Machine

Automatic 8 Spindles Air-Coil Winding Machine

Frequently Asked Questions #

What types of winding machines are available?

DETZO offers a variety of winding machines, including bifilar-type multilayer winding machines, 10-spindle winding and soldering machines, as well as solutions for air-core and flat-wire winding.

Which materials are compatible with these machines?

DETZO winding machines are designed to process copper wires, flat wires, and other specialized materials used in inductor manufacturing.

What is the maximum wire gauge supported?

Wire gauge compatibility depends on the specific model, with options available for both fine and thick wires to suit different applications.

Are customization options available?

Yes, DETZO provides customization to address unique production requirements, such as specialized wire tension systems or custom winding patterns.

Is post-sales support provided?

DETZO offers technical support, spare parts, and maintenance services to ensure the long-term performance of their machines.

Explore More #

For a complete overview of DETZO’s winding solutions and to find the right machine for your needs, visit the one-stop winding solutions page or browse the full product catalog.