The Role of Transformer Coil Winding in Modern Manufacturing #

Transformers are essential static devices composed of two or more windings. They function by transforming AC voltage, current, and impedance through electromagnetic induction. The invention and widespread use of transformers have significantly advanced the electric power industry, making them a fundamental component in modern society.

Beyond transformer coils, related products such as inverter coils, rectifier coils, filter coils, and ignition coils are commonly found in everyday applications. For manufacturers seeking to optimize production, automated equipment is recommended for various coil-related products. For further assistance or specific requirements, contact DETZO.

Key Functions and Structure of Transformers #

The primary function of a transformer is voltage conversion. At its core, a transformer contains primary and secondary windings, both made from wound coils. The transformer coil winding machine is designed to precisely wind wires or coils onto the transformer core. The quality and configuration of these windings directly influence the transformer’s electrical performance and voltage conversion capabilities, making the winding machine a critical tool in transformer manufacturing.

Common Transformer Coil Winding Types #

Different winding designs can impact a transformer’s energy conversion efficiency, output voltage stability, and load adaptability. Here are three widely used winding methods:

1. Crossover Winding #

Crossover winding involves placing the primary and secondary windings crosswise on the core, interspersed and distributed at different locations. This design reduces mutual inductance between windings, minimizes leakage flux, and enhances transformer efficiency.

2. Spiral Winding #

Spiral winding arranges the primary and secondary windings in a spiral pattern around the core, forming a continuous spiral structure. This method is typically used in high-power transformers, offering improved electrical performance and stability.

3. Disc Winding #

Disc winding wraps wires or coils around the core in a disk-shaped configuration. This approach effectively controls the electromagnetic field, boosting efficiency and performance. It is often applied in high-voltage or specialized industrial transformers.

Advantages of Using Winding Machines for Transformer Production #

1. Precision #

Transformer coil winding machines provide accurate control over coil winding, ensuring consistent size, number of turns, and positioning for each winding. This precision enhances manufacturing quality.

2. Automation and Efficiency #

Automated winding machines streamline the winding process, completing tasks faster than manual methods. This reduces labor costs, shortens manufacturing time, and increases overall productivity.

3. Consistency and Stability #

By automating the winding process, manufacturers can maintain uniform quality and stability, reducing variability and ensuring reliable product performance.

Why Choose DETZO Transformer Winding Machines? #

DETZO’s transformer winding machines are engineered to improve accuracy, efficiency, and quality stability in transformer coil manufacturing. With comprehensive technical support, training, and responsive after-sales service, DETZO helps customers meet production demands while optimizing costs.

Related Equipment for Transformer Manufacturing #

Benchtop 2 Spindles Taping Machine

Benchtop 2 Spindles Taping Machine

Benchtop 4 Spindles Taping Machine

Benchtop 4 Spindles Taping Machine

Automatic Magnetic Core Assembly Machine

Automatic Magnetic Core Assembly Machine

Automatic E I Silicon Steel Sheet Assembly TIG Welding Machine

Automatic E I Silicon Steel Sheet Assembly TIG Welding Machine

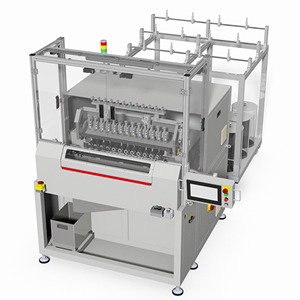

Low Frequency Transformer Coil Production Line

Low Frequency Transformer Coil Production Line

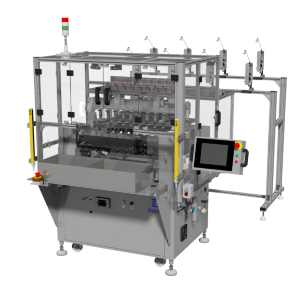

High Frequency Transformer Coil Production Line

High Frequency Transformer Coil Production Line

Automatic 8 Spindles Coil Winding Machine

Automatic 8 Spindles Coil Winding Machine

Automatic 6 Spindles Coil Winding Machine

Automatic 6 Spindles Coil Winding Machine

Automatic 8 Spindles Transformer Coil Winding Machine

Automatic 8 Spindles Transformer Coil Winding Machine

Automatic 12 Spindles Coil Winding Machine

Automatic 12 Spindles Coil Winding Machine

Automatic 8 Spindles Bobbin Coil Winding Machine

Automatic 8 Spindles Bobbin Coil Winding Machine

Automatic 8 Spindles Horn Coil Winding Machine

Automatic 8 Spindles Horn Coil Winding Machine

For more information on transformer coil winding machines and related solutions, explore the Multi-Spindle Coil Winding Machine category or reach out for tailored support.