Understanding Inductors and Their Role in Modern Electronics #

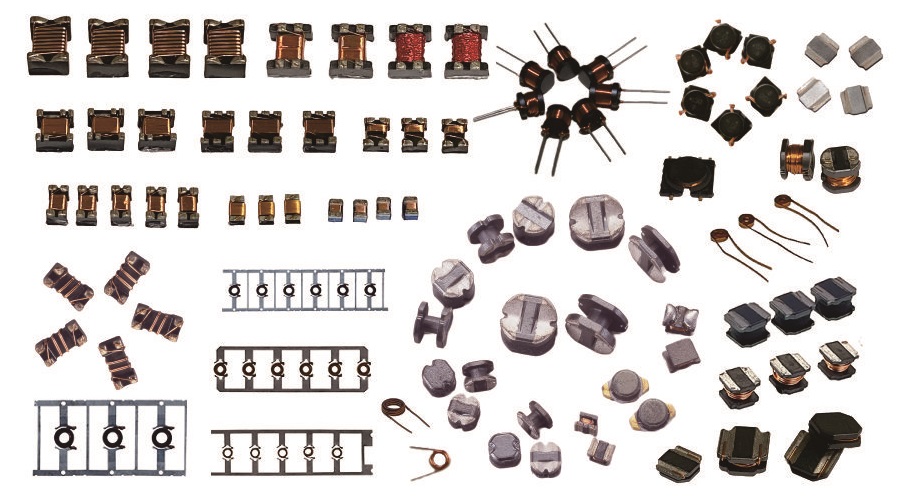

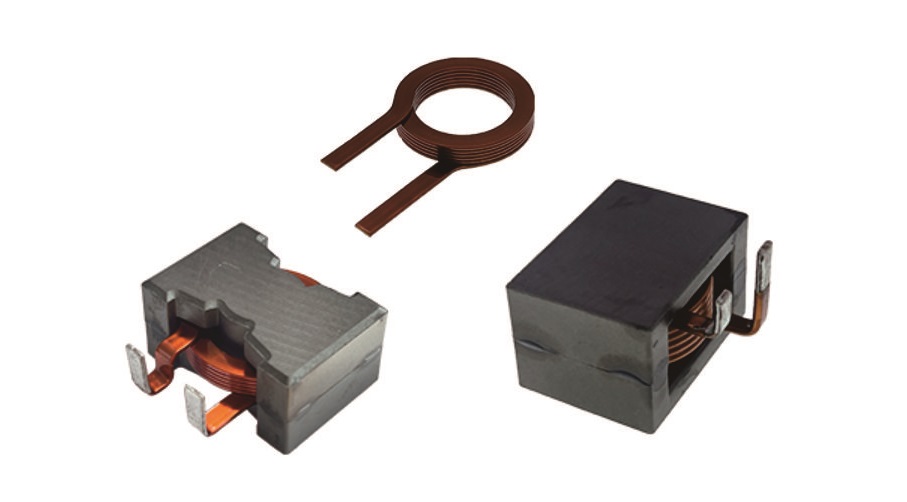

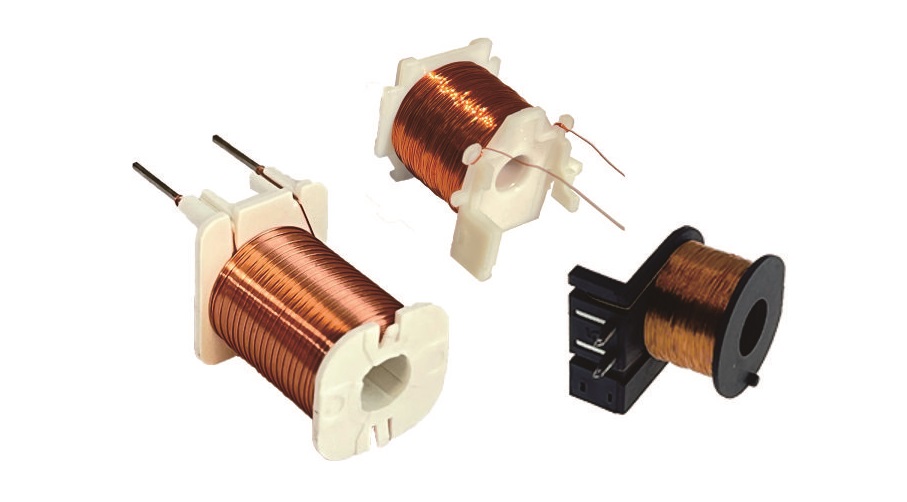

An inductor is a passive electronic component formed by winding copper wire around a core or bobbin, resulting in a specific number of turns and a defined appearance. This construction imparts electromagnetic properties to the component, known as inductance. The resulting wound coil, often referred to as an inductor coil or simply an inductor, is widely used for filtering and power conversion in electronic circuits. In certain cases, air-core coils are produced using specialized processes to meet unique application requirements.

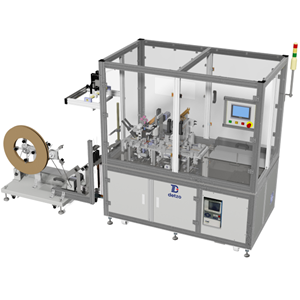

DETZO offers a range of automated production equipment tailored for inductor-related products. For those seeking solutions such as Inductor Winding Machines, DETZO provides both standard and customized options to address diverse manufacturing needs. Contact DETZO for further information or to discuss your specific requirements.

What is an Inductor? #

An inductor, also known as an inductor coil, is a passive component consisting of a coil of wire wound around a core material. Its primary function is to resist changes in the flow of electric current by generating a magnetic field around the coil, thereby storing and controlling electrical energy in the form of magnetic energy. This property makes inductors essential in a wide range of electrical and electronic applications.

Key Applications of Inductor Coils #

1. Transformers #

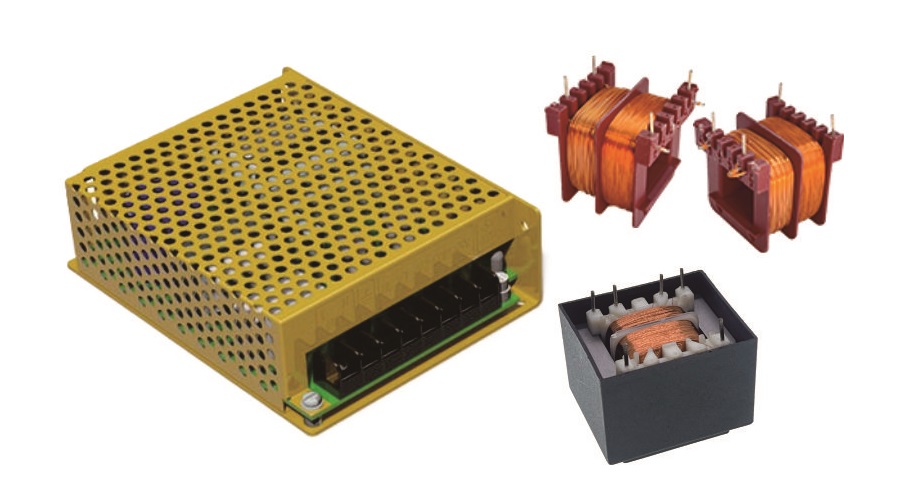

Inductor coils serve as the core elements in transformers, enabling the conversion of electrical energy from one voltage level to another. They also provide electrical isolation and facilitate efficient energy transfer, making them indispensable in transformer design.

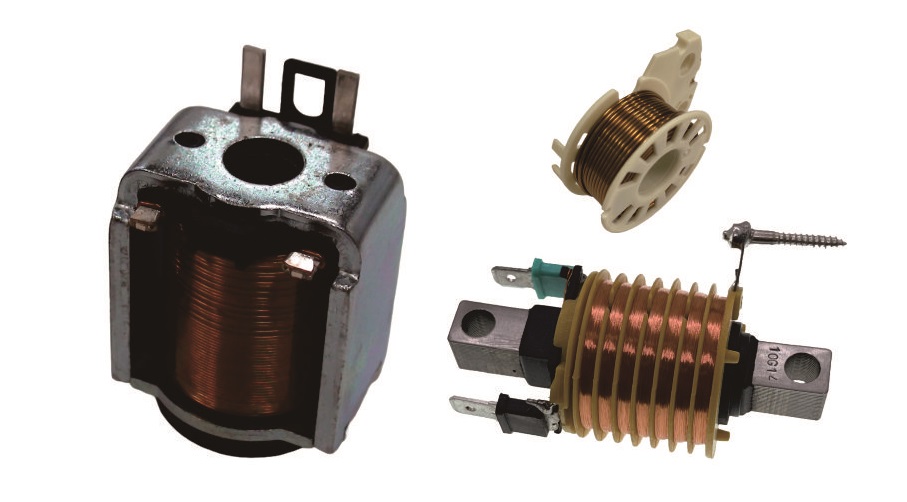

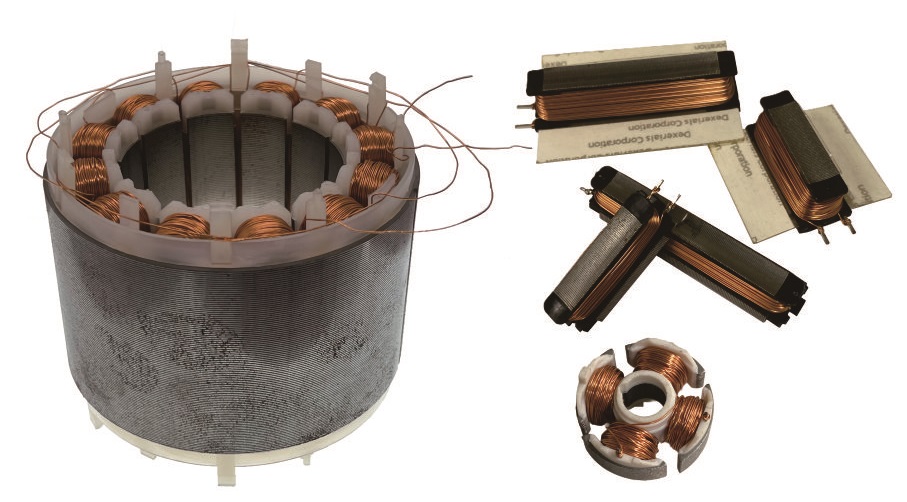

2. Motor and Generator Windings #

Inductors are integral to the windings of motors and generators, where they generate magnetic fields and electromagnetic forces. This enables the conversion of electrical energy to mechanical energy in motors, and vice versa in generators. Inductor coils can be customized to suit various motor and generator configurations.

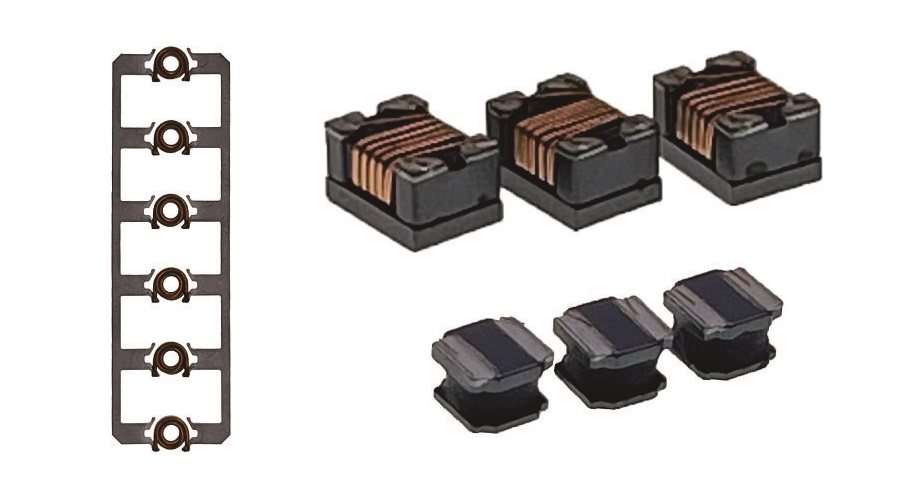

3. Filters #

In electronic circuits, inductor coils act as frequency-dependent elements, introducing inductive reactance that allows selective passage or attenuation of certain frequency components. They are crucial for low-pass filtering, noise reduction, signal conditioning, and impedance matching, shaping the frequency response of circuits.

4. Energy Storage Devices #

Inductors store energy in their magnetic field when current flows through them, releasing it back into the circuit as needed. This capability supports energy storage, filtering, voltage regulation, current limiting, and energy conversion, making inductors vital in power supplies and energy storage systems.

5. Analog and Radio Frequency Circuits #

In RF circuits, inductors enhance gain and sensitivity by providing inductive reactance for signal amplification or by tuning circuits to specific frequencies. This allows for precise reception or transmission of signals at desired frequencies.

Advantages of Using Inductor Coil Winding Machines #

Precision and Consistency #

Automated inductor coil winding machines deliver consistent winding with precise control over the number of turns, wire tension, and layering patterns. Integrated sensors and monitoring systems detect faults or irregularities during winding, ensuring high product quality and minimizing defects. This consistency is essential for maintaining the desired electrical properties of inductors.

Increased Efficiency and Cost Savings #

Automatic winding machines optimize wire usage and tension, reducing material waste and accelerating production compared to manual methods. Continuous operation minimizes human error, increases output, and lowers labor costs, resulting in a more cost-effective manufacturing process.

Customization and Flexibility #

Modern winding machines can be programmed to produce a variety of inductor coil types and specifications, enabling manufacturers to address a broad spectrum of requirements without extensive retooling.

Why Choose DETZO Inductor Winding Machines? #

DETZO provides a comprehensive selection of inductor coil winding machines, ranging from simple manual models for small-scale production to advanced, fully automated systems for industrial applications. Each solution is tailored to meet specific production requirements, ensuring optimal performance and efficiency. In addition to individual machines, DETZO offers complete planning and customization for automated production and assembly lines, supporting streamlined manufacturing and enhanced productivity.

Contact us today to discuss your project and receive a solution tailored to your needs.

Related Products #

Automatic Inductor Cover Assembly Machine

Automatic Inductor Cover Assembly Machine

Automatic Flat-Wire Inductor Winding Machine

Automatic Flat-Wire Inductor Winding Machine

Automatic Inductor Soldering Machine

Automatic Inductor Soldering Machine

Automatic Core Gluing Machine

Automatic Core Gluing Machine

Automatic 8 Spindles Air-Coil Winding Machine

Automatic 8 Spindles Air-Coil Winding Machine

Automatic Inductor Coreless Winding Machine

Automatic Inductor Coreless Winding Machine

Automatic 10 Spindles Inductor Winding & Soldering Machine

Automatic 10 Spindles Inductor Winding & Soldering Machine

Automatic 2 Spindles Inductor Winding Machine

Automatic 2 Spindles Inductor Winding Machine

Automatic Bifilar-Type Multilayer Inductor Winding Machine

Automatic Bifilar-Type Multilayer Inductor Winding Machine

Car Accessories

Car Accessories Valve

Valve Solenoid

Solenoid Solar Power

Solar Power Relay

Relay BLDC Motor

BLDC Motor Transformer

Transformer Inductor

Inductor