Introduction to BLDC Motor Winding #

Brushless DC motors (BLDC motors) have become a cornerstone in modern electric motor technology, offering efficiency and reliability across a wide range of applications. At the heart of their production lies the precision of coil winding, a process that determines the performance and durability of the final motor.

What is a BLDC Motor? #

A BLDC motor is an electric motor that operates without brushes and a commutator. Instead, it uses electronic control to adjust the stator current, generating torque based on the position of the rotor’s permanent magnets. Despite the name, a BLDC motor is technically a permanent magnet synchronous motor (PMSM) that utilizes three-phase electricity. The term “brushless DC motor” is used because these motors can replace traditional brushed DC motors in many scenarios. To distinguish them from mechanically commutated motors, they are also referred to as EC (electronically commutated) motors.

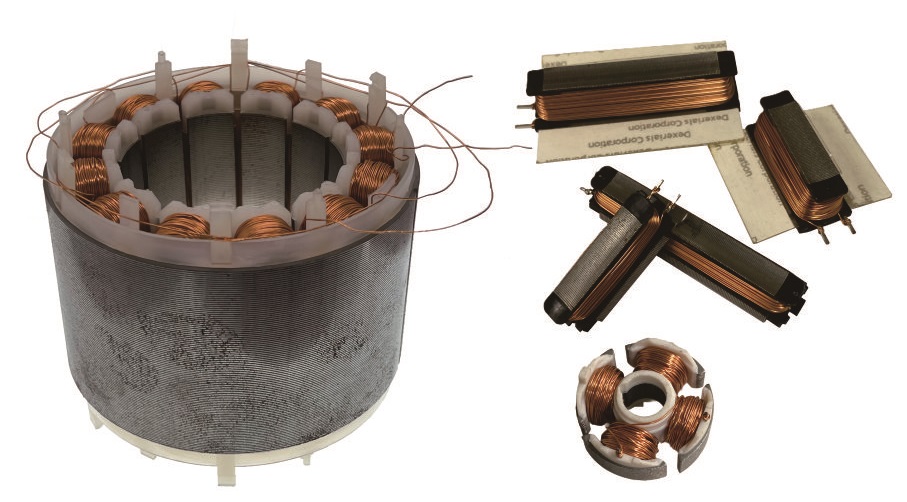

Types of BLDC Motors #

BLDC motors are generally categorized into two types:

- Inner Rotor BLDC Motors: The rotor is located inside the stator winding.

- Outer Rotor BLDC Motors: The rotor surrounds the stator winding.

Each type offers unique advantages depending on the application, such as improved cooling or higher torque density.

The Role of Winding Machines #

The quality and consistency of the winding process are critical for BLDC motor performance. DETZO’s BLDC motor winding machines are engineered to produce both inner and outer rotor BLDC motors, ensuring precise coil placement and repeatable results for industrial-scale production.

If you have specific requirements for brushless DC motor coil winding, you are welcome to contact DETZO for tailored solutions.

Related BLDC Motor Winding Solutions #

Automatic Fan Motor Winding Machine

Automatic Fan Motor Winding Machine

Automatic Outer Motor Stator Winding Machine

Automatic Outer Motor Stator Winding Machine

Automatic Inner Motor Stator Winding Machine

Automatic Inner Motor Stator Winding Machine

3 Phase BLDC Motor Winding Machine

3 Phase BLDC Motor Winding Machine

PMSM Motor Stator Winding Machine

PMSM Motor Stator Winding Machine

Motor Stator Coil Assembly Production Line

Motor Stator Coil Assembly Production Line

Automatic Flyer type Stator Winding Machine

Automatic Flyer type Stator Winding Machine

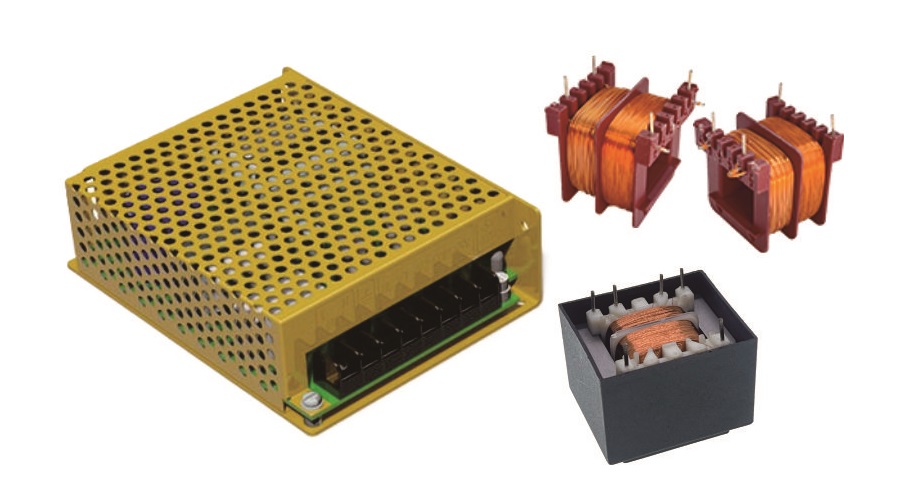

Transformer

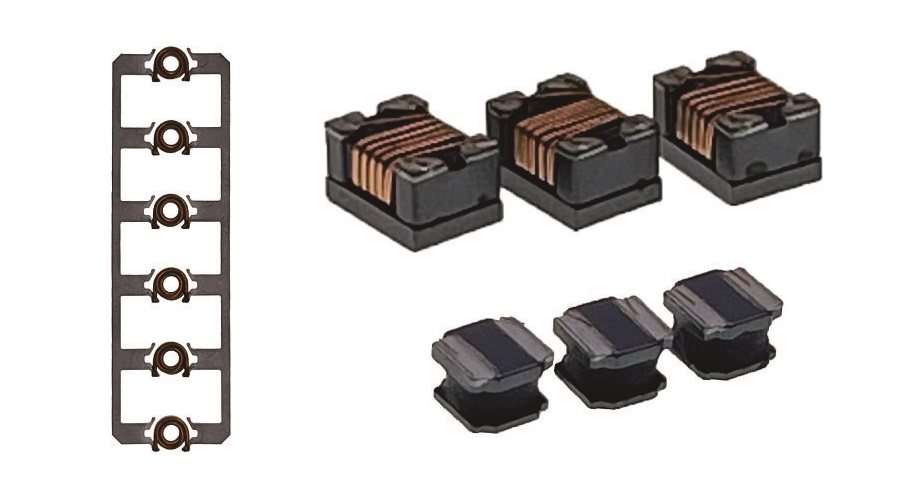

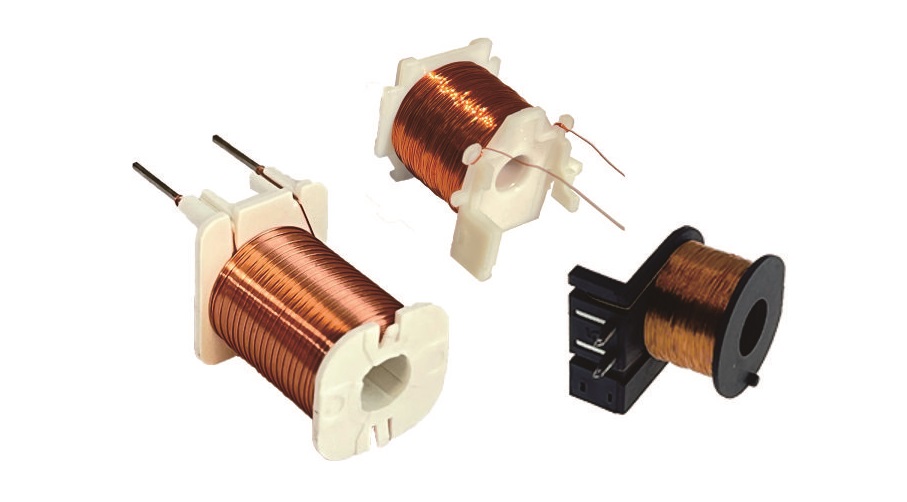

Transformer Inductor

Inductor Car Accessories

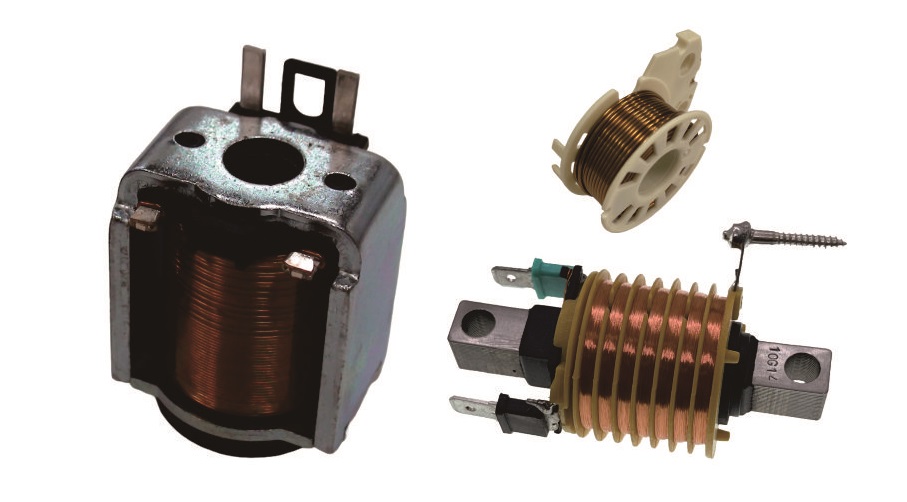

Car Accessories Valve

Valve Solenoid

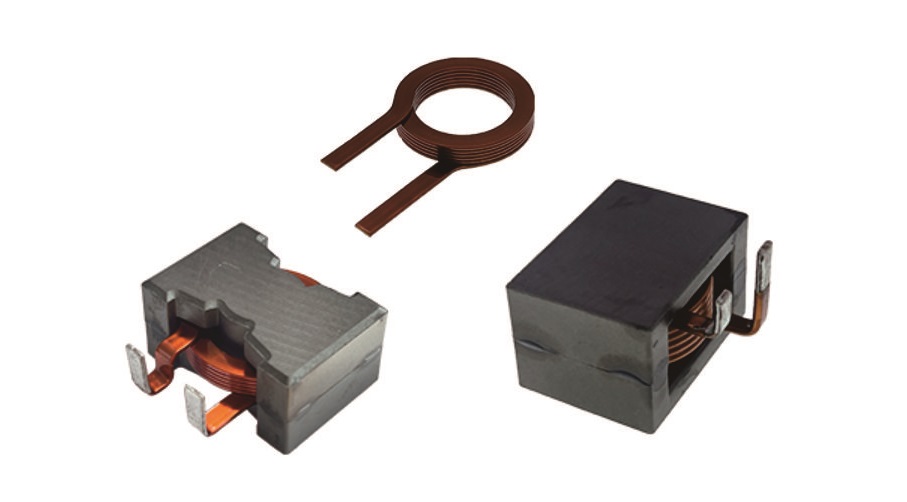

Solenoid Solar Power

Solar Power Relay

Relay BLDC Motor

BLDC Motor